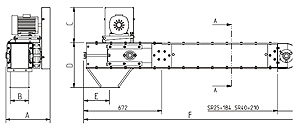

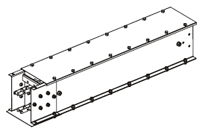

The pit chain conveyor is machinery for loading the grain. It is assembled in a pit which is made of concrete. Thanks to its bearing capacity and special build-up the pit chain conveyor conveys the grain in the horizontal direction. The conveying machinery can be changed, it can be expanded according to the costumers’ demand. The optional accessory of the machinery is a 15o or a 30o bend. The machinery can convey grain with this accessory. It can be used for material with flour.

- Galvanized build-up

- More possibilities to connecting, loading and uploading

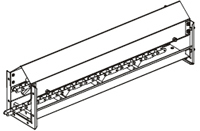

- The round rotated elements are self-cleaning

- Low power demand

- Gentle conveying

- Total discharge (every fifth blade cleans the conveyor totally)

Capacity

(in the case of clean, dry barley)

| Type | SR25 | SR40 | SR60 | SR80 | SR100 | SR120 |

|---|---|---|---|---|---|---|

| Capacity t/h | 25 | 40 | 60 | 80 | 100 | 120 |