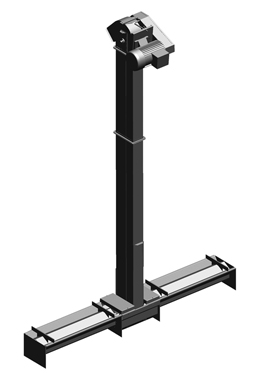

It can be used where safety and capacity is required. The chain conveyor is a simple and fail-safe solution for conveying a large amount of grain vertically and at an angle. The conveyor needs an extremely small place. The chain conveyor consists of massive steel construction, it is dust-free and needs little maintanence. It has long life because of its high qualified bearing.

Characteristics:

- Galvanized surface

- The lower sprocket consists of two parts therefore the outage.

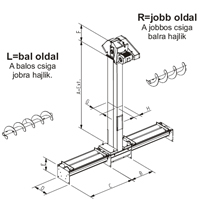

- Because of the wide range of products the chain conveyor can be assemblied in many ways according to the demands.

- The discharging angle can be raked in 45o

- There is a double house at the driving.

- The lengthening elements will be galvanized after welding