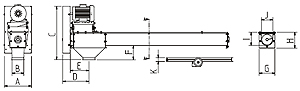

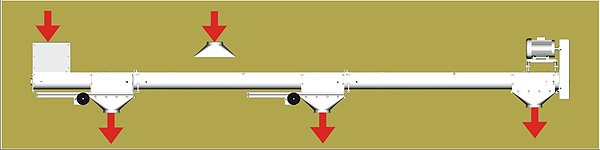

The trough auger conveyor is used for conveying grain, feed, meal groats or materials that can be bulked in a horizontal angle or in acclivity. The trough auger can be produced in different assembling modes. More connecting possibilities can be chosen at the inlet and the outlet. 20-30 t material can be conveyed by the trough auger. It is suggested to grain, meal groats or materials that can be bulked in a horizontal angle or in acclivity. The trough auger can be used for loading silos or emptying flat silos.

- Galvanized build-up

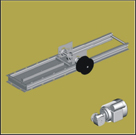

- A double house at the power axle

- A divided intermediate bearing, made of special alloy

- Extensions are galvanized after welding