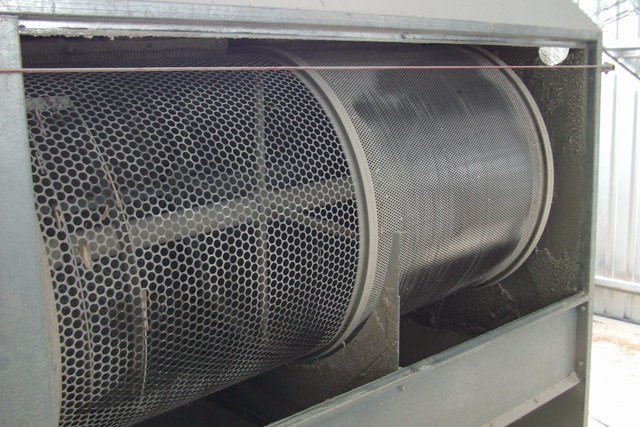

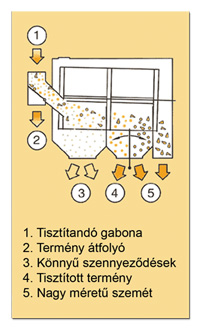

The rotating drum cleaner detaches the contamination and the rest of stem in grain. The crop gets into the rotating roll then goes through the chaffer with different sizes. Then the crop drops out of the adequate halls during this time the contamination leaves the end of the cylinder. The diameter of the chaffer holes depends on the type of the crops, its humidity and contamination. The drum screens with different holes clean and selects grain. The inclination of the drum screens can be adjusted by hand. During operation plastic brushes clean the screens. The efficacy of the cleaning can be adjustable. The driving of the cleaner with a rolling drum is provided by a strong motor with gearbox.

Rotating drum cleaners

| Type | PPR2/6 | PPR3/6 | PPR4/6 | PPR2/9 | PPR3/9 | PPR4/9 | PPR3/12 | PPR4/12 | PPR5/12 | PPR5/16 |

| Capacity** (t/h) | 20 | 30 | 40 | 50 | 75 | 100 | 125 | 150 | 200 | 260 |

| The surface of the chaffers (m2) | 2,5 | 3,75 | 5 | 5 | 7,5 | 10 | 11,5 | 15,5 | 19 | 25 |

| The number of the chaffers | 2 | 3 | 4 | 2 | 3 | 4 | 3 | 4 | 5 | 5 |

| The capacity of the motor (kW) | 0,75 | 1,1 | 1,1 | 1,1 | 2,2 | 2,2 | 3 | 4 | 5,5 | 7,5 |

| Length* (mm) | 2170 | 2820 | 3470 | 2960 | 3810 | 4660 | 4300 | 5205 | 6115 | 6358 |

| Width* (mm) | 800 | 800 | 800 | 1100 | 1100 | 1100 | 1400 | 1400 | 1400 | 2018 |

| Height* (mm) | 1345 | 1345 | 1345 | 1800 | 1800 | 1800 | 2215 | 2215 | 2215 | 2591 |

| Empty weight (kg) | 310 | 405 | 525 | 540 | 625 | 810 | 1280 | 1450 | 1700 | 2540 |

| Charged weight (kg) | 370 | 485 | 630 | 630 | 750 | 970 | 1535 | 1740 | 2050 | 3160 |

| Capacity (m3) | 2,3 | 3 | 3,7 | 5,9 | 7,5 | 9,2 | 13,3 | 16,1 | 18,9 | 34 |